It's good to be back.

Since I left off with my last post on my Mk.II reactor, I have made much progress. I have had the chamber machined, gone through two different power supplies, acquired a bottle of deuterium, and gotten an ultra high vacuum system working.

Before I go into any more detail on my current apparatus, I'm just gonna recap how the fusor works in Layman's terms:

The vacuum chamber is pumped down to a very low pressure, and a high negative voltage is applied to the inner grid, which is a spherical electrode in the center of the chamber. The outside of the chamber is left grounded. Due to electrostatic field emission from the grid, the gas in the chamber is ionized, forming a plasma. These gas ions are positively charged, and due to the inner grid's strong negative charge, they are accelerated towards it. In the center of the grid, some of the ions collide. If the gas in the chamber is deuterium (hydrogen-2), the two colliding deuterium nuclei will fuse into a helium-3 nucleus and eject a fast neutron. The nucleus then will remix with electrons emitted from the grid and become neutral.

Just to start off, here is a picture of my current setup:

.

Now for a quick walkthrough of the different sections of the reactor...

Now for a quick walkthrough of the different sections of the reactor...

The Chamber:

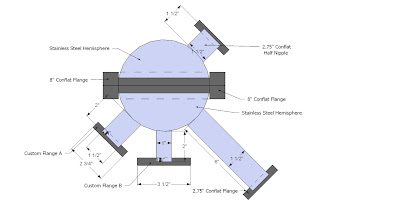

The reactor's stainless steel, spherical chamber was machined with the help of Tom Egan at Mercury Machine Company's machine shop, and my deepest thanks goes out to them, I really couldn't have done this without their excellent work. The chamber has a 1.5" wide viewport, a high voltage feedthrough port, a port connecting to an air cooled diffusion pump, a 6" long tube for a future ion source, additionally, there are two 3/8" NPT ports on the top of the chamber for vacuum gauging and a soon to come gas system. The flanging on the chamber is a mixture of commercial and custom hardware. Both the pump flange and the feedthrough flange are ISO-esque flanges in which an o-ring is pressed against a flat plate, forming a seal. The 8" diameter flanges holding the halves of the chamber together, as well as the 2.75" flanges on the ion gun tube and viewport are conflat-type flanges. In a conflat flange, a copper gasket is pinched tightly between two "knife edges" on either flange. This creates a very strong seal between the flanges.

High Voltage System:

High Voltage System:

Originally, I had planned to use an x-ray transformer to power the fusor, and later I decided on using a two stage, lines frequency voltage multiplier to run the reactor, constructed of 2 stages of 2 banks of 16 microwave capacitors, driven by a few neon sign transformers (In the future, I plan to use this supply, however with a distribution transformer powering it). However, recently, I was graciously given a 30kV Glassman high voltage power supply, which I currently am using to power the reactor. The

supply uses a simple D25 connector to interface with a simple controller I made for it.

The Vacuum System:

The fusor's vacuum system consists of two pumps, a rotary vane mechanical pump, and a air cooled, oil diffusion pump. The mechanical pump first pulls the chamber down to a pressure of around 160 millitorr -1/4750th of atmospheric pressure. At this point, the diffusion pump is turned on. A diffusion pump is a type of ultra-high vacuum pump that uses fast moving heated oil to pump a gas from a chamber. The diffusion pump will bring the overall system pressure down to less than one millitorr of pressure. The diffusion pump can be throttled by a variac that controls the oil heater's voltage.

Pictures of Runs:

Three loop grid, pressure around 10 millitorr

Two loop grid, pressure around 5 millitorr

Toroidal grid